Aug 20, 2023

Can 6,000 Cr GreyOrange Build Robots from India to the World?

Profile

Retail

Series B-D

B2B

Technology

Last fortnight, GreyOrange announced it had 5,000 robots in operation all across the world, as it was named Spark’s leading autonomous mobile robot vendor in the world

Sparking Circuits

Akash Gupta and Samay Kohli were students at BITS Pilani.

In 2007, they met through their shared passion for science and mathematics, which led them to pursue robotics at BITS’ Center for Robotics & Intelligent Systems (CRIS).

At CRIS, they would go on to build Acyut, India’s first humanoid robot. They then represented the country in global humanoid robotics championships, winning the Gold Medal at the San Francisco RoboOlympics in 2009.

This would start a long and successful partnership between the two.

Around the same time, Wolfgang Hoeltgen, an electronics engineer at IBM and an entrepreneur, was organising a science and technology show in Germany. He invited the duo to present Acyut in Hannover.

Akash and Samay were deeply inspired by Wolfgang’s experience across research, manufacturing, engineering and software development and approached him to act as their mentor.

This would continue for the next few years, as the duo would contact Wolfgang occasionally to share their ideas with him.

An internship at C&C Technologies in the United States would give Akash and Samay their first exposure to a product that would later become the heart of their entrepreneurial venture.

At C&C, a company primarily focused on surveying and mapping terrain, Akash and Samay were tasked with developing a small Disney park (400 sq. ft.) with the special effects entirely automated. This would be the first time Akash and Samay were involved in a project of such scale.

Shortly after that, the duo started GreyOrange in 2011 from their savings of Rs 5 lakhs during their internship in the US. They initially pursued the field of robotics training and began teaching at universities.

They immediately understood that dwelling in education was not their cup of tea. They decided to move over to the service industry and began finding business opportunities where they could provide value.

Before the internet was mainstream in India, a company was building robots.

Thinking, Inside A Box

To truly understand which industry they could fit into, Akash and Samay set themselves some essential criteria.

They wanted the problem to be global, the solution to the problem to be disruptive enough and the solution to involve both hardware and software.

In 2012, a visit to a Flipkart warehouse in Delhi gave Akash and Samay the opportunity they were looking for.

The warehouse was cluttered with piles of different products spread entirely throughout the floor, and people needed help sorting and picking up all the products.

The chaos at the warehouse made an ideal scenario for the duo to explore.

They were convinced that they could build an elegant robotics system, backed by complex software, that could help warehouse workers pick and move the products much more efficiently.

As they had done in the past, they contacted their mentor Wolfgang and presented their newest idea. Upon hearing the idea, he was convinced that it was the perfect match of the duo’s skills and real worldwide demand.

He immediately flew to India and helped work out a business plan.

Within a month, he liquidated his life insurance, rented office space, bought a CNC (computer numeric control) and hired engineers.

Flipkart would give them their first order of Rs 35 Lakhs to build a warehousing solution, and just like that, GreyOrange Robotics would have its start.

The duo shared a lofty vision, imagining warehouses run entirely and managed by robots.

They ran into early hurdles though, as the need for a language to allow communication among multiple robots, and of a proper prototyping environment in India, meant that they had to build everything from scratch.

The GreyOrange Butler Robot System was the first product they would start working on.

It consisted of Butler Robots, autonomous mobile robots, Pick/Put stations where the warehouse employers could interact with the product, Mobile Storage Units and Charging Stations. The centre of the system was GreyMatter, an end-to-end order fulfilment platform that controlled and managed all the devices to drive collaboration.

Alongside the Butler, they set out to build the Sorter, even though they were a team of barely 10. The Sorter would be a mobile warehouse sorting capability to sort packages/products based on rules.

Armed with a massive vision, changes in e-commerce were afoot

Brain Racking Problems

For two years, the team would switch between building the Butler and the Sorter.

Building them in parallel was not possible, due to the complexity of the problem. Three years after its conception, the first robot butler system would be installed in Hong Kong, with 10 mobile butler units.

The Sorter would be a part of the Flipkart warehouses in Bangalore. DTDC would be onboarded soon, and many more were to follow.

The end of 2012 would see GreyOrange receive their first-ever VC funding from the BITS Spark Angel group.

This group of BITS Pilani alumni globally invested in BITSian-founded Indian startups. The round would see GreyOrange compete with 23 startups and become the only one that received funding.

GreyOrange saw a massive demand for their robotics solutions as they showed more and more value to their existing customers.

Flipkart reported picking items from 100-120 in eight hours to 400-600 per hour. DTDC could handle 20-25% more daily volume at each hub. The shipment turnaround of 6-7 hours now dropped to 1-2 hours.

While more and more companies wished to adopt GreyOrange’s solutions, they chose to be selective in picking who to partner with for their next generation of robots. They preferred installations in Singapore and in international markets.

They soon moved to Singapore as a base, giving them better operational flexibility and access to the rest of Asia.

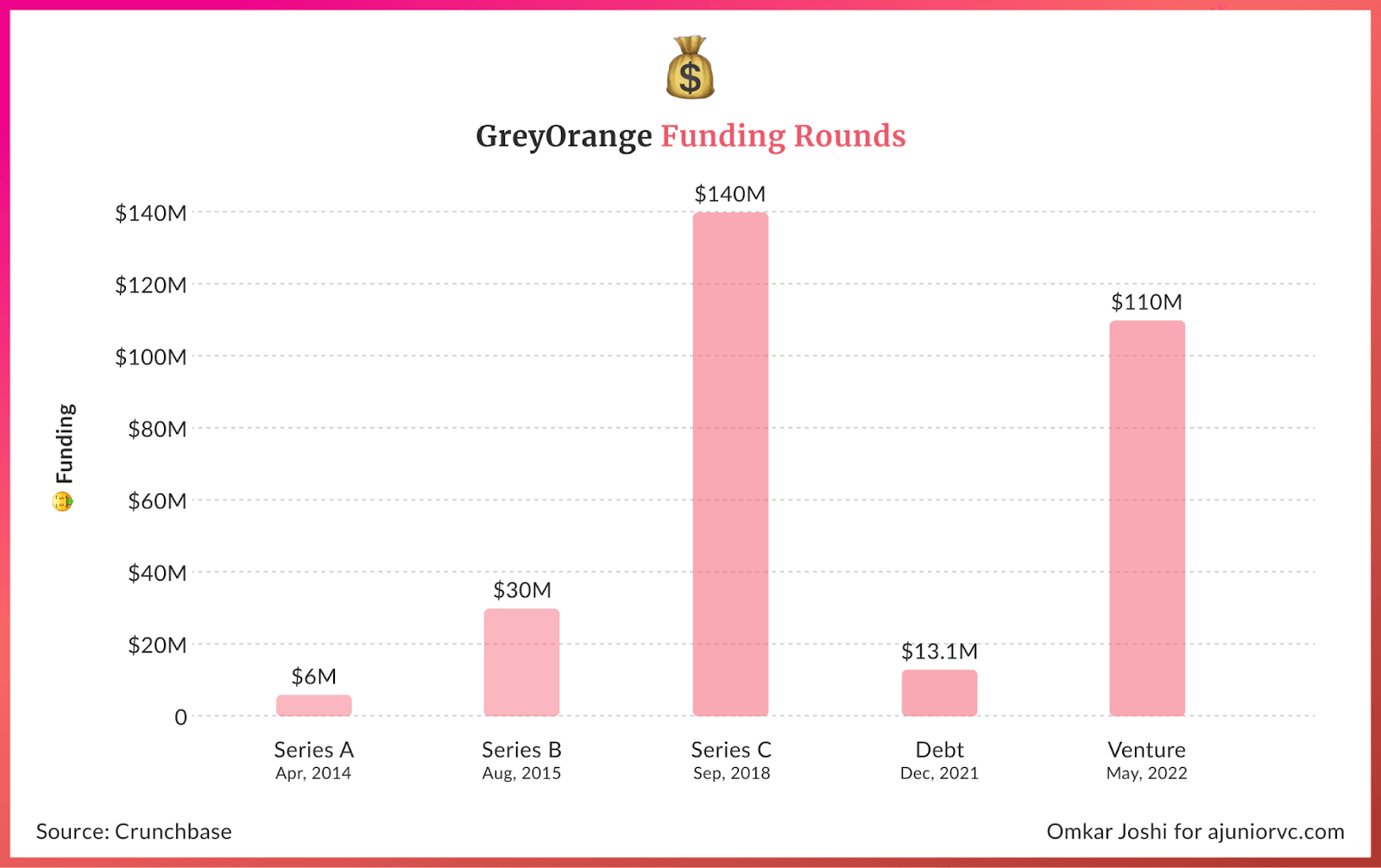

2014 saw GreyOrange raise Rs 54 Crores as its Series A funding, as a means to scale internationally and focus on R&D to improve the autonomy and efficiency of their systems.

With supply chain efficiencies primed to be a pivotal factor for global trade in the upcoming decade, GreyOrange were right in the midde of solving a massive global pain point.

GreyOrange Robotics had begun making their mark, not just in India, but across the globe.

Forklifting Spirits

Samay and Akash recognised the transformative potential of robotics and automation across industries, but as newcomers, they wanted to focus their efforts early on.

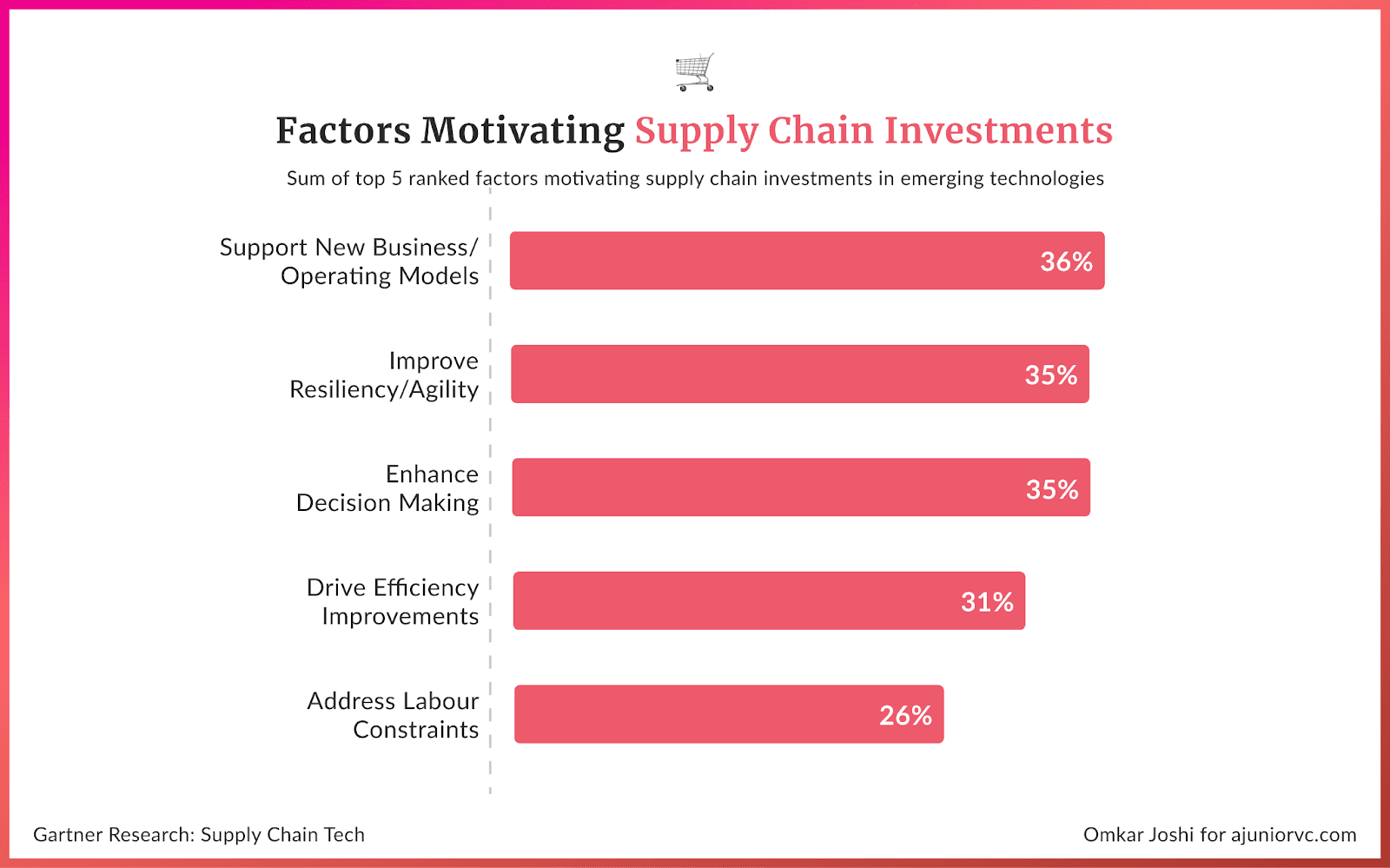

By 2015, the e-commerce industry was soaring domestically and globally, revealing scalability gaps. Within this realm, warehousing and fulfilment emerged as labour-intensive bottlenecks in the supply chain.

Yet, labour shortages were rampant and projected to persist. An astounding 73 per cent of third-party logistics firms highlighted the struggle to secure, train, and retain skilled labour as their foremost challenge.

Moreover, high training expenses, labour efficiency limitations, and constraints in handling volume within tight timeframes plagued the warehousing sector. The alluring promise of 1-day e-commerce delivery unveiled the vulnerabilities of manual labour.

Technology emerged as the crucial component to facilitate sustainable scaling.

After thorough industry exploration, the team honed in on the e-commerce, burgeoning retail, and consumer goods sectors. The surge in e-commerce and logistics, both internationally and domestically, offered many opportunities.

Around the world, companies were excitedly adopting and investing in warehouse robots. These robots were helping businesses and their workers handle challenges like higher costs, lots of orders, shortage of staff, and tight deadlines, all while making fewer mistakes.

Amazon’s acquisition of Kiva in 2012 was a highlight of this trend. At a time when the global logistics and warehouse robot market was expected to grow to over $125 billion within the next decade, Samay and Akash discovered a niche and went all-in.

They began by locally creating and selling their technology, expanding their customer base.

Around the same time, India introduced the GST (goods and services tax), greatly benefiting GreyOrange.

This new tax system encouraged businesses, including e-commerce players, to use centralised warehousing instead of having warehouses in each state, which was the norm before GST that aided companies to avoid entry taxes. This shift to centralised warehousing opened doors for automation, where GreyOrange excelled.

By 2016, their customers included prominent names like Flipkart, Myntra, DTDC, GoJavas, and Jabong in the e-commerce and logistics sectors. In just five years, the startup achieved nearly 90% of the market share of India's warehouse automation market, establishing a near monopoly.

Acknowledging the fierce competition in the industry, they emphasized research and development (R&D), with over a third of their workforce dedicated to it. This strategic focus would open a myriad of opportunities for the team.

A science project had transformed into a real company, with a big moment for the company soon to arrive.

Loaded Docks

Home Logistics' Osaka centre selected GreyOrange Butler for warehouse automation in 2017

Despite having numerous alternatives, GreyOrange won. This decision held significance beyond the local context, marking GreyOrange's foray into the exacting tech landscape of Japan and its stringent requirements.

GreyOrange's accomplishments shine for their impressive technology skills and knack for navigating an arduous journey. The company's entry into complex global markets showcased its software, hardware, electrical, and mechanical engineering expertise.

GreyOrange's progress soared as time passed, achieving a remarkable 300% year-on-year growth by 2017.

Unstoppable in their pursuit, GreyOrange's founders harnessed their deep understanding of automation to achieve remarkable success. What began with modestly paid trials swiftly evolved into substantial contracts, with single warehouse deployments worth between $10 million and $20 million.

GreyOrange founders relied on hands-on experience, gathering practical insights during warehouse visits as the automation landscape evolved.

As the autonomous warehouse era began its adoption cycle, GreyOrange's dedication to continuous improvement remained evident. They focused on agile hardware, holistic software solutions, and platforms to flexibly vary warehouse operations.

Their dedication to high standards led to implementing a "10x KPI," ensuring that GreyOrange installations delivered a tenfold increase in cost savings or time efficiency for their customers.

With the consignment processing capacity soaring tenfold, GreyOrange's technology emerged as a potent tool in minimising human errors in labelling and routing, especially valuable for courier companies like DTDC.

Beyond efficiency, GreyOrange was equally dedicated to enhancing customer onboarding, a critical component in their journey. They achieved this by delivering installation times a quarter of the industry average, reducing downtime and optimising resources, unlike the conventional approach of immediate large-scale installations.

GreyOrange's robotic "Butlers" real-time capabilities boosted efficiency and curtail costs. As their fleet of robots grew, implementing smart orchestration became paramount. Optimal task assignments reduced onboarding and support costs and streamlined operations to an impressive degree.

Embracing the industry's advancements, GreyOrange surged ahead, achieving a notable break-even point in 2019, realised within less than a decade since its inception.

In just five years, their revenue mix also underwent a transformative shift. While remaining a significant contributor, India accounted for 10% of the total revenue, the United States claimed half, and the remainder flowed in from Europe and Japan.

The company was building from India to the world.

Plane Spaces

The foundation of GreyOrange's ambition demanded a corresponding scale of solutions.

The company would investing over $1 million to set up its U.S. headquarters in Atlanta, Georgia. Spanning a sprawling 110,000 sq. ft. office and warehousing space, this campus strategically positioned GreyOrange to tap into the city's well-established supply chain and logistics provider network.

Complementing this move, the creation of an R&D unit in Boston aimed to attract top-tier tech talent from renowned educational institutions across the globe.

Meanwhile, GreyOrange expanded its footprint into Japan and Germany as its workforce neared the 600-mark. This expansion necessitated the cultivation of diverse talent and ecosystems across different locations.

Despite this growth, the company's commitment to technology remained steadfast, with more than a third of its workforce dedicated to research and development.

In a significant stride forward, GreyOrange introduced its flagship Fulfilment Operating System in December 2019, incorporating the innovative GreyMatter intelligence as a learning layer within Ranger GTP (Butler), Ranger Mobile Sorter (Flexo), and Ranger Picking (PickPal).

Ranger Mobile Sorters transported parcels from receipt to dispatch. Ranger Picking Pickpal collaborates with robots to assist or fulfill tasks. Fulfilment Operating System enhanced store efficiency by precisely packing orders.

The ranger robots communicate to recalibrate priorities and strategies in real-time, considering commitments, speeds, availability, and windows.

By 2020, the company had scaled to an astonishing 1,000 Cr of revenue. This was not just an incredible feat for an Indian startup but also one for making robots from India.

Amidst these advancements, GreyOrange was not alone in the race to revolutionise warehouse automation.

Sorting Out The Competition

Amazon set the precedent for nearly a decade before the pandemic instigated a seismic shift in global supply chains.

Fulfilment operations, especially susceptible due to staffing shortages brought about by social distancing and isolation measures, were suddenly ripe for transformation – an opportunity that robots seemed poised to seize, in part if not in entirety.

GreyOrange was in global contention alongside half a dozen rapidly burgeoning players in warehouse automation and fulfilment management.

The field included the likes of Geek+, Alibaba's favoured warehouse robotics creator; InVia, headquartered in Los Angeles, which leased automated robotic technologies to fulfilment centres; Gideon Brothers, a Croatian startup; Berkshire Grey, one that amalgamated AI and robotics to automate the fulfilment processes of retailers, e-commerce entities, and logistics enterprises; Quicktron from Germany and Canada's Otto Motors, among others.

The space would see massive amounts of capital. Geek+ would raise $2.8B, Berkshire Grey would go public, raising $2.5B, and Invia and Gideon would each raise $200M.

While emerging challengers showcased their novel innovations, GreyOrange also faced stiff competition from industry stalwarts such as Swisslog, SSI Schaefer, Siemens, Daifuku, and Mitsubishi, all of whom showcased offerings transcending mere robotics and fulfilment, expanding their influence across various domains.

The industry's ultimate aspiration remained steadfast: developing intelligent, integrated solutions fusing IoT, 5G, edge computing, and real-time computer vision to supplant traditional conveyor-belt assembly lines.

Key differentiators would be affordability, deployment speed, and scalability.

GreyOrange's distinctive strength resided in its ability to deploy systems within a remarkable timeframe of under six months, starkly contrasting to the 12-18 months demanded by conventional automated storage and retrieval systems.

This accelerated implementation, coupled with the option for gradual scaling, avoided upfront investments and underutilisation during the initial phases, effectively positioning GreyOrange as a formidable contender in its sphere.

As the fulfilment industry reached a staggering $9 billion, with the promise of swift expansion as automation permeated every facet of production and logistics, the market structure seemed poised to evolve into an oligopoly gradually over time.

However, the world would watch this industry face rapid changes, as the unforeseen challenges brought on by the pandemic would completely disrupt supply chains across the globe.

Bionic Arms Race

Pre-pandemic, the warehousing sector had been on a slow burn

Innovation and automation upgrades were limited due to the prevailing perception of warehousing as a cost centre. Efficiency was often sought through cost reduction rather than technological advancement.

However, the pandemic proved to be a seismic catalyst, disrupting the supply chain sector and prompting a complete 180-degree shift in approach. As the pandemic unfolded, the traditional methods of scaling operations became untenable.

This unprecedented situation fueled an unparalleled demand for robotics in the manufacturing sector.

During this crucial juncture, the demand for robots skyrocketed, with large retailers desperately seeking solutions to meet the new needs of efficiency and speed. Amazon deployed an astonishing million robots in its warehouses to accommodate the surge in e-commerce demands, while other retailers needed help managing 20-30K robots.

The post-pandemic era heralded the beginning of the "Robot Wars."

In this landscape, Amazon introduced Kiva, Alibaba embraced Geek+, and GreyOrange emerged as the choice for other retailers. The company became a pivotal robot supplier to many prominent clients, including Walmart, H&M, COS, Coupang, and GXO Logistics.

GreyOrange experienced rapid growth across diverse customer bases, applications, and geographic regions, further underscored by achieving a remarkable 170% gross retention in contracted revenue from existing customers in 2021.

The demand for GreyOrange's omnichannel fulfilment platform grew immensely post-pandemic.

Retailers worldwide came to acknowledge robotic automation in the fulfilment process. This marked an extraordinary moment when an Indian-origin hardware company was shining on the global stage, actively onboarding customers across diverse countries ranging from the United States to Japan.

In a significant milestone, GreyOrange secured $110 million in funding, strategically fueling global expansion, consolidating market dominance, enhancing the deployment of their industry-defining software platform, and accelerating the adoption of their cutting-edge solutions worldwide.

Despite the growth, 2022 would be a rough year for GreyOrange as they would scale slower than their competitors in the gold rush. The company had a planned IPO at a $1.6Bn that wouldn’t materialize. Investors would nudge for a change.

The change would come.

Picked-And-Packed Future

As the company entered 2023, it would see changes in its team

Samay Kohli would move on as the CEO of the company, with his co-founder Akash picking up the mantle. The team would also beef up its management team, looking more like a global organization.

Despite the challenges faced by GreyOrange, its journey would be exceptional. Lacking any sort of ecosystem in India for hardware, it emerged as a global leader.

Becoming Spark’s leading autonomous mobile robot vendor would be no mean feat.

As the team is organized for scale, substantial growth still beckons. Retailers worldwide will actively seek avenues to enhance their supply chain capabilities, creating a sustained demand for innovative solutions.

GreyOrange's estimation of the addressable market further bolsters this conviction.

Globally, the percentage of smart warehouses remains small, ranging from 8-10%, and some countries, like the UK, possess a mere 2-3% smart warehouses.

GreyOrange has thus made significant investments into expanding its leadership team. Strategic appointments such as a regional CEO for North America and a global COO are steps to unlock growth potential fully.

It plans to introduce an additional 300 roles spanning engineering, product development, and marketing and assemble a formidable team.

Hitting an estimated $150M in revenue in 2022, the company looked better positioned to win in 2023.

GreyOrange continues to emphasise product quality and the prowess to introduce pioneering projects. The company's inception was rooted in the conviction that fulfilling modern demands must rely on something other than technology tailored for a bygone era.

Remaining true to its foundational principle, GreyOrange recently unveiled a multi-robot orchestration feature, enabling robots from different manufacturers to function collaboratively within a warehouse setting.

This innovation aligns with their anticipation that by 2026, more than 50% of companies deploying intralogistics robots will embrace a multi-agent orchestration platform.

From a modest courier service in India to a cutting-edge logistics warehouse in Osaka, GreyOrange's journey has transcended expectations.

It is a humbling and awe-inspiring embodiment of "Make in India for the World." The journey has merely commenced as the company progresses, promising a bionic future.

Writing: Bhoomika, Ajeet, Raghav, Mitali, Nikhil and Aviral Design: Omkar and Stable Diffusion